Indirect bonding

Indirect bonding software

The aim is to create a guide tray for transferring the brackets to the patient’s teeth.

The software is used to design this tray by virtually placing the brackets on the teeth using the method of your choice, and finally to produce the tray by thermoforming or direct 3D printing.

Main advantages of this method over direct bonding :

- Greater precision in bracket orientation and placement

- Better patient comfort

- Reduced chair time

- Fast and simple workflow

Step-by-step instructions:

- Selection of the desired bracket series from the catalog of most major manufacturers (Ormco, …).

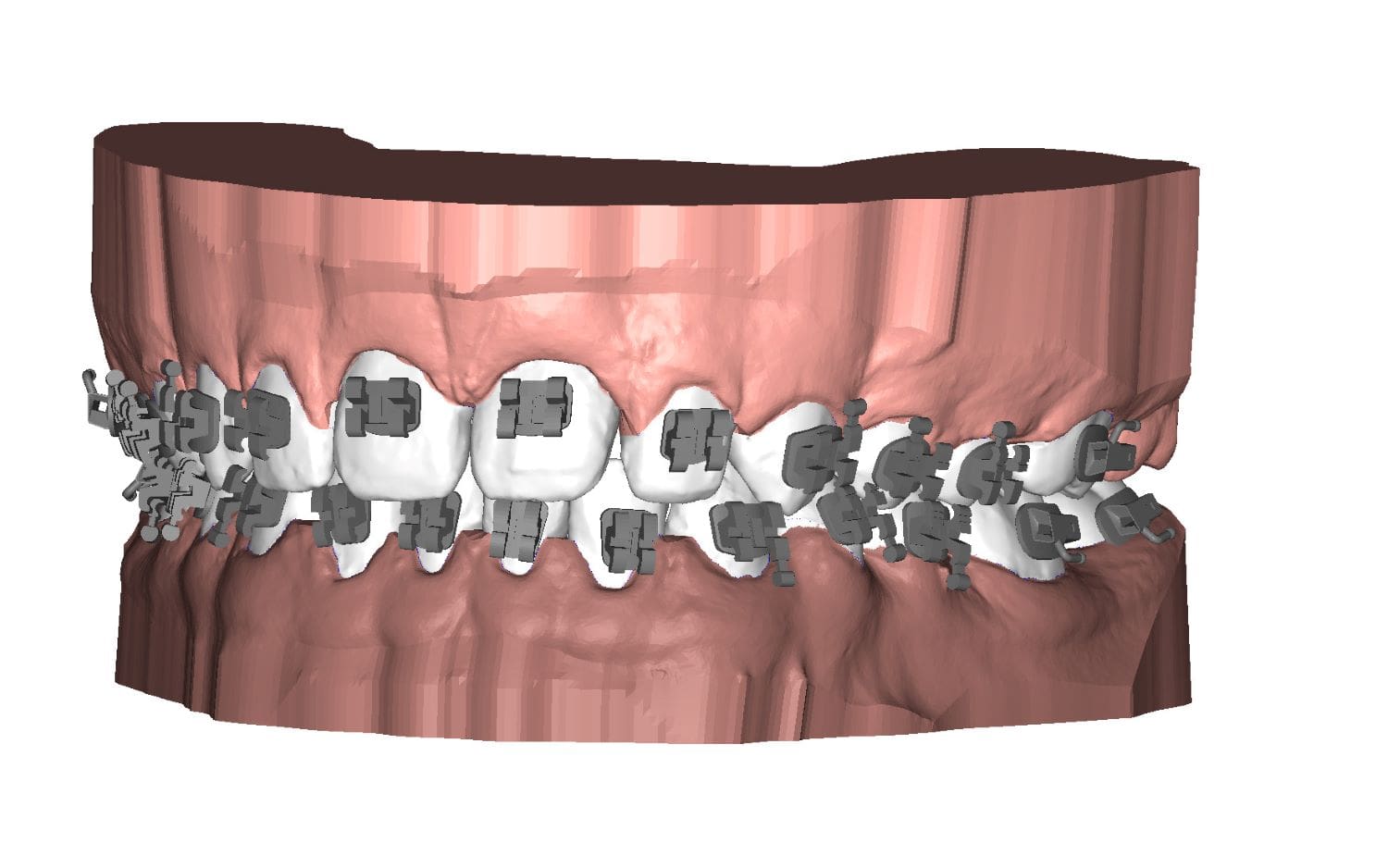

- Automatic positioning of brackets on the FA point of each tooth

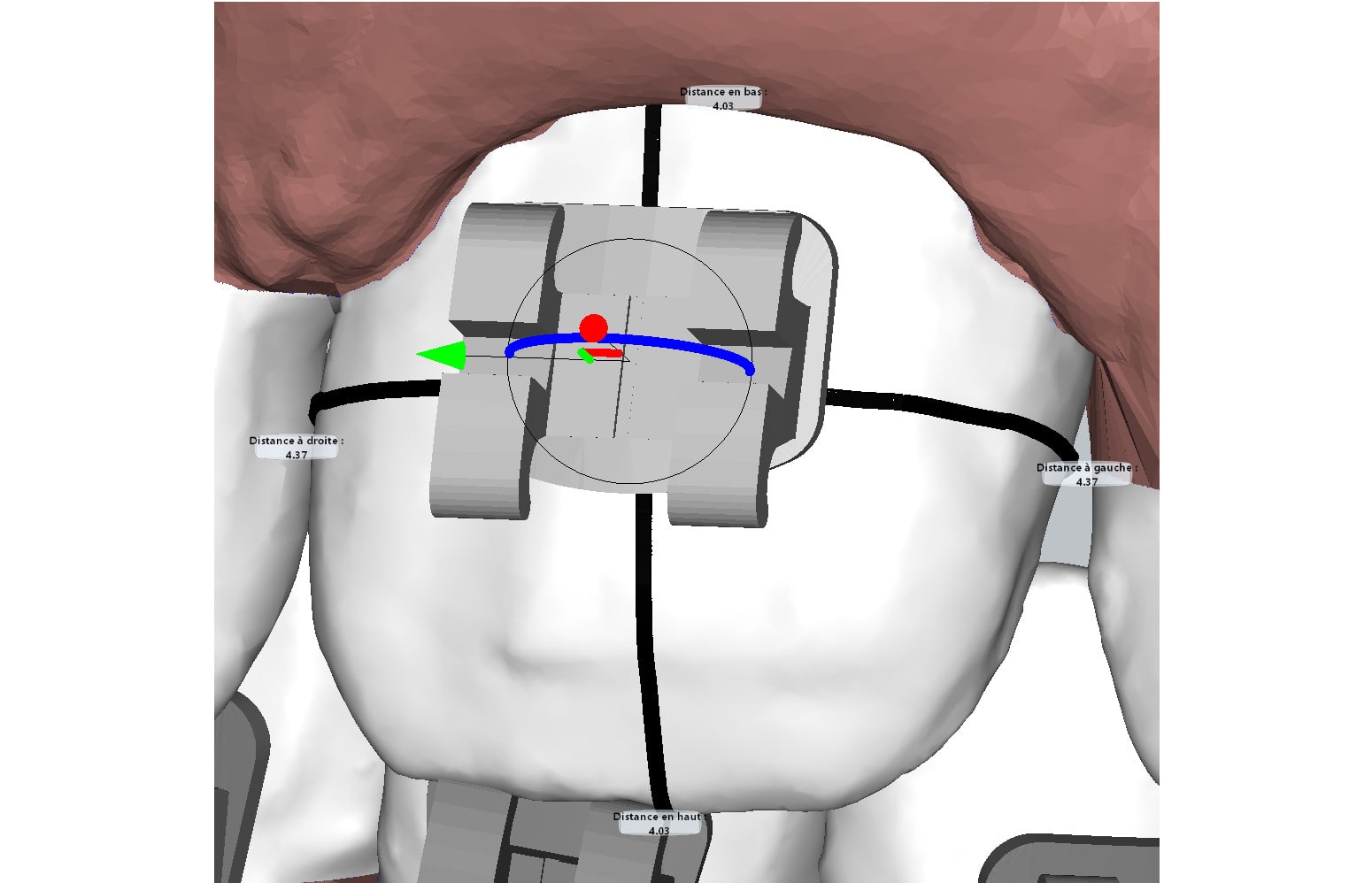

- Bracket position adjustment using a known method (Andrews, Roth, Wick Alexander, Step Dwight Damon, MBT). The software displays the markings and measurements on the vestibular surfaces of the teeth in real time, enabling high precision.

- Export of the dental model to be printed in 3D, for production using thermoforming and silicone foil.

- Or export the mouthpiece itself, for 3D printing with silicone resin.

The final step is to place the actual brackets in the transfer tray.

Now you’re ready to place the brackets on the patient!

Adjustment of bracket position

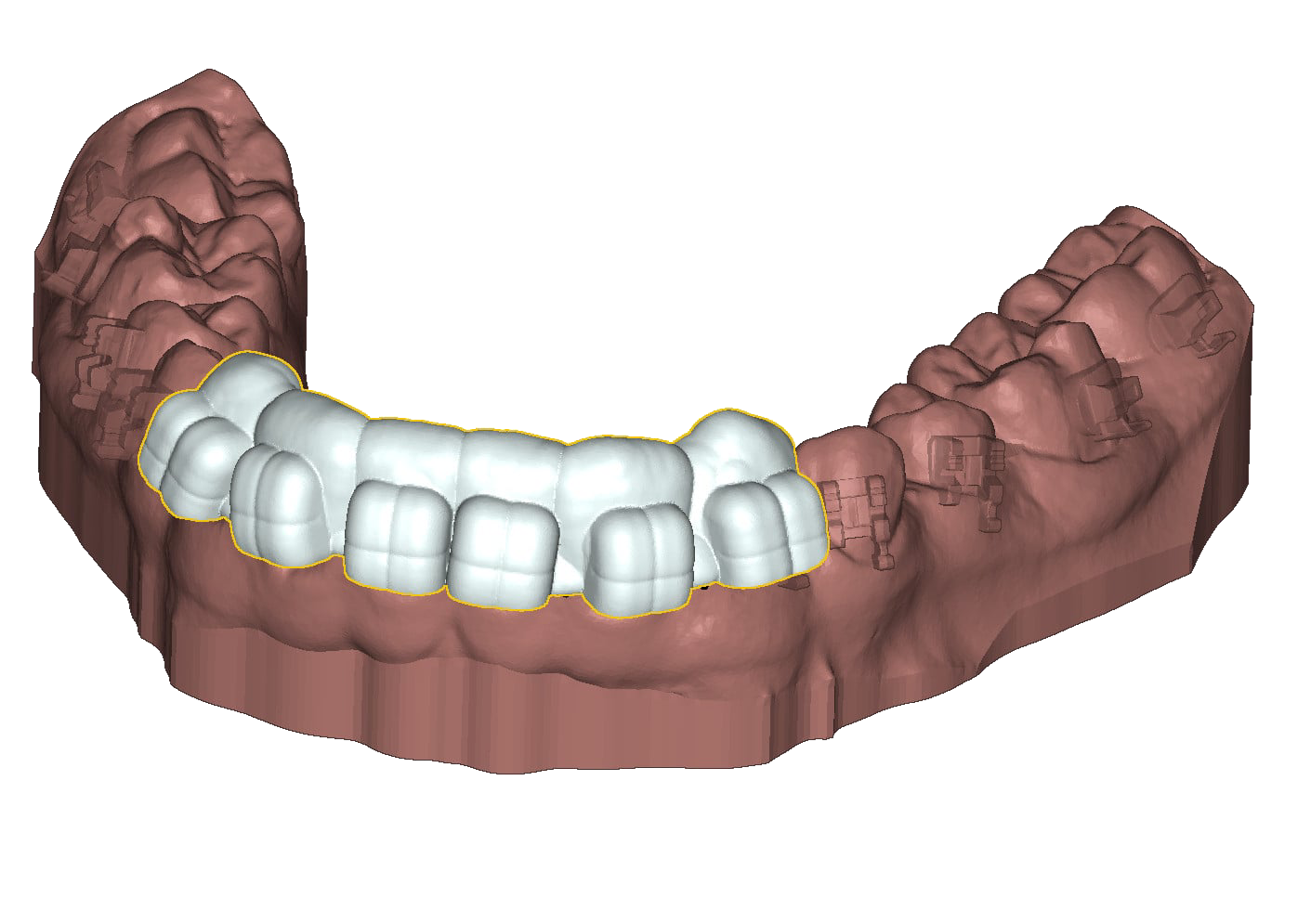

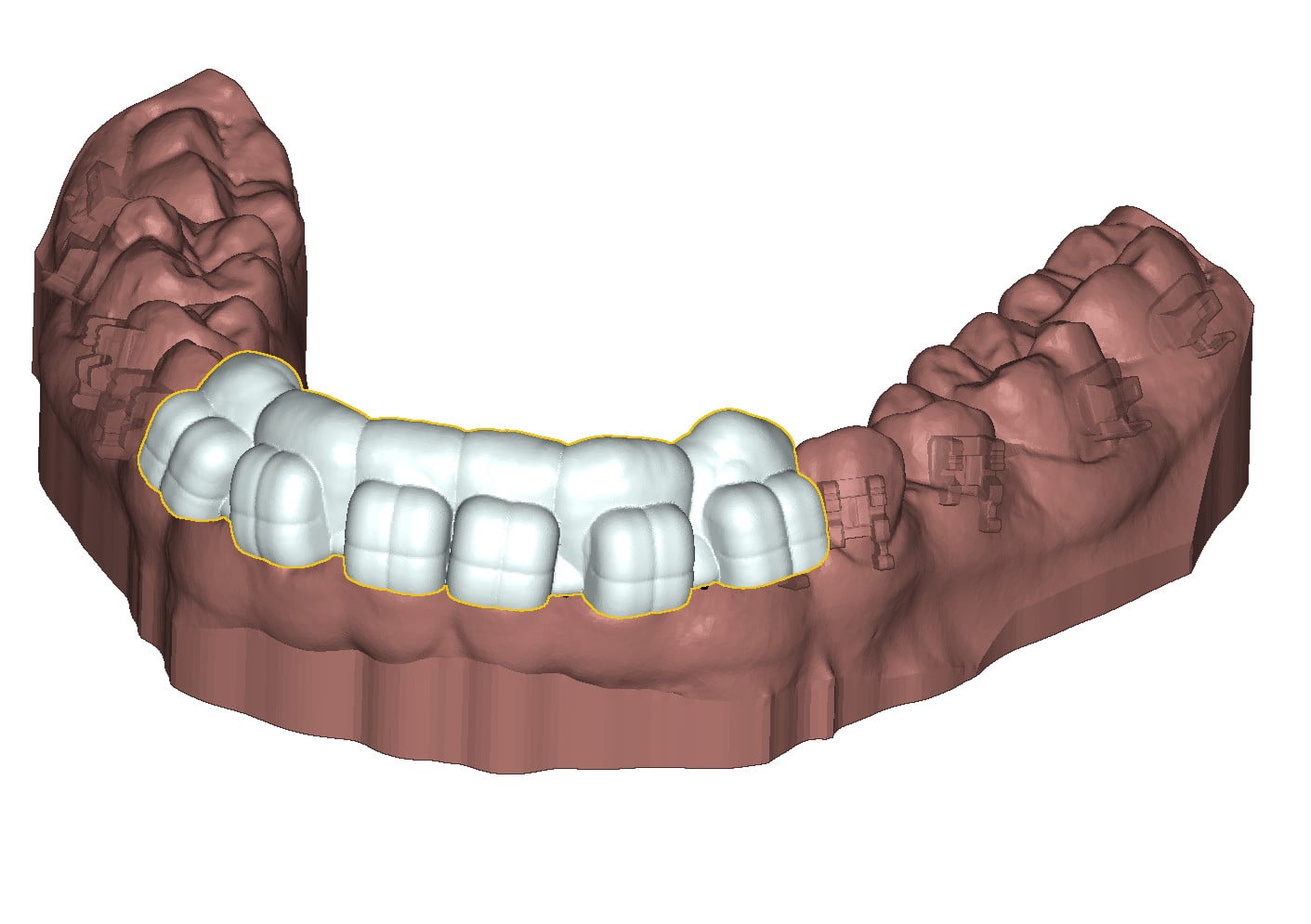

Automatic bracket placement with FA point

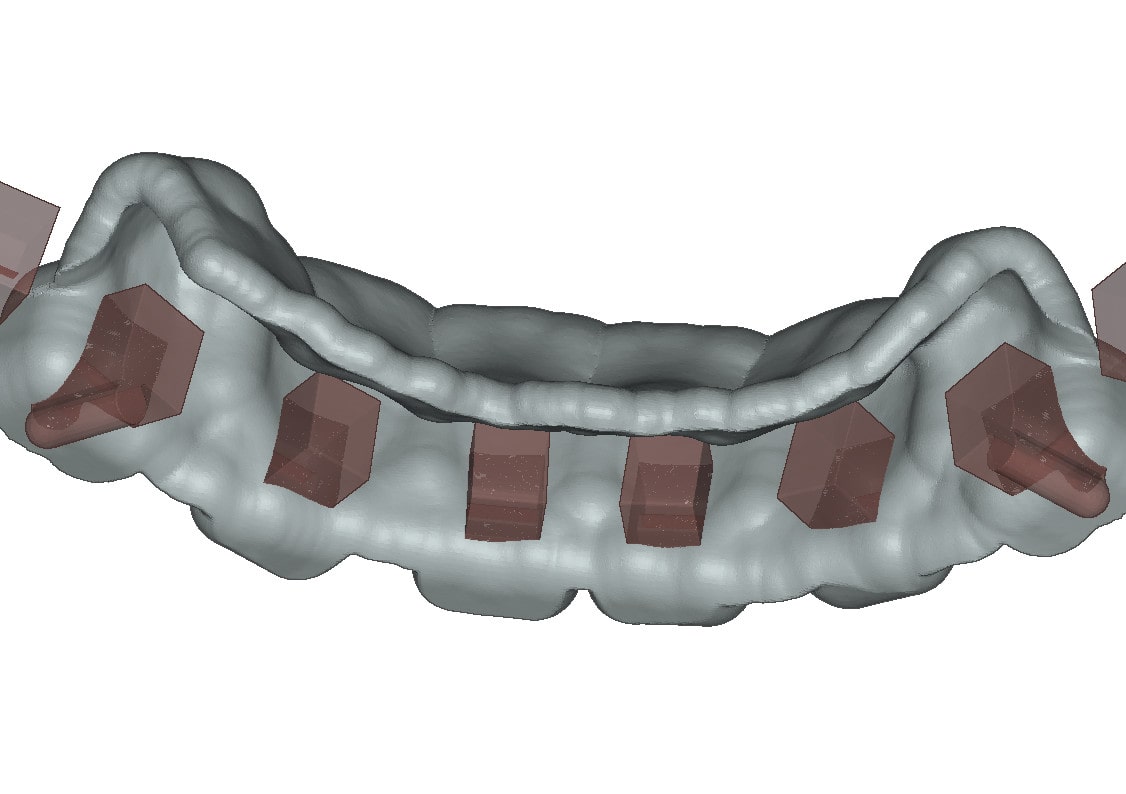

Creation of the indirect bonding tray

Undercuts are automatically taken into account to facilitate bracket insertion

List of bracket manufacturers already compatible:

- Aditek

- Dentaurum

- DTC Orthodontics

- Forestadent

- GC Orthodontics

- GNI

- Leone

- Morelli

- Ormco

- Orthodeal

- Orthometric

- RMO

List of bracket manufacturers non compatible:

- 3M orthodontics

- American Orthodontics

Other manufacturers are available on request.

For the moment, this traditional method is only available for vestibular orthodontics.

Related articles: The Indirect Bonding Technique in Orthodontics – A Narrative Literature Review